MozziWatch has long established relationships with trusted production partners across the world. We pride ourselves on working with only the most sustainable and ethical suppliers.

At all Eucalyptus plantation sites:

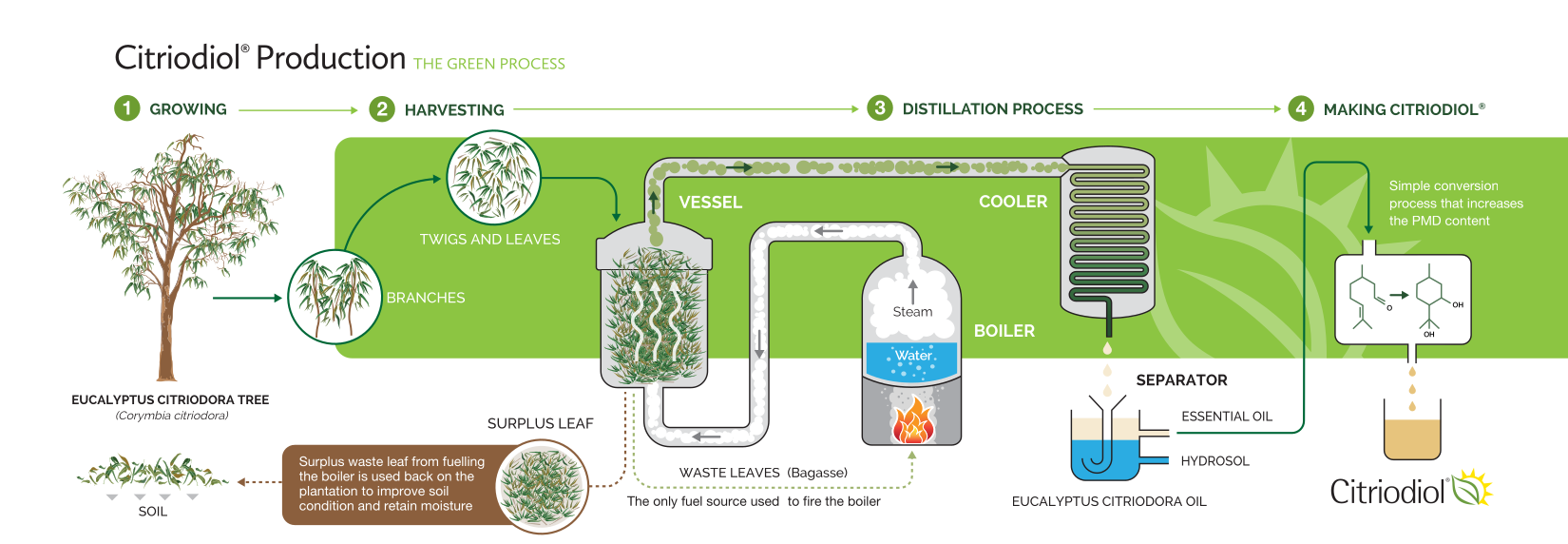

Harvesting the leaves

As the demand for Citriodiol increases so do the number of trees planted to produce our oil. These plantations are sustainably managed by local partners.

ZERO Waste – The trees that are cut down are specially treated for use as poles or sold to local businesses. Remaining wood is used as fuel for the water boiler in the distillation process or mulched and used as fertiliser.

Distillation of the oil